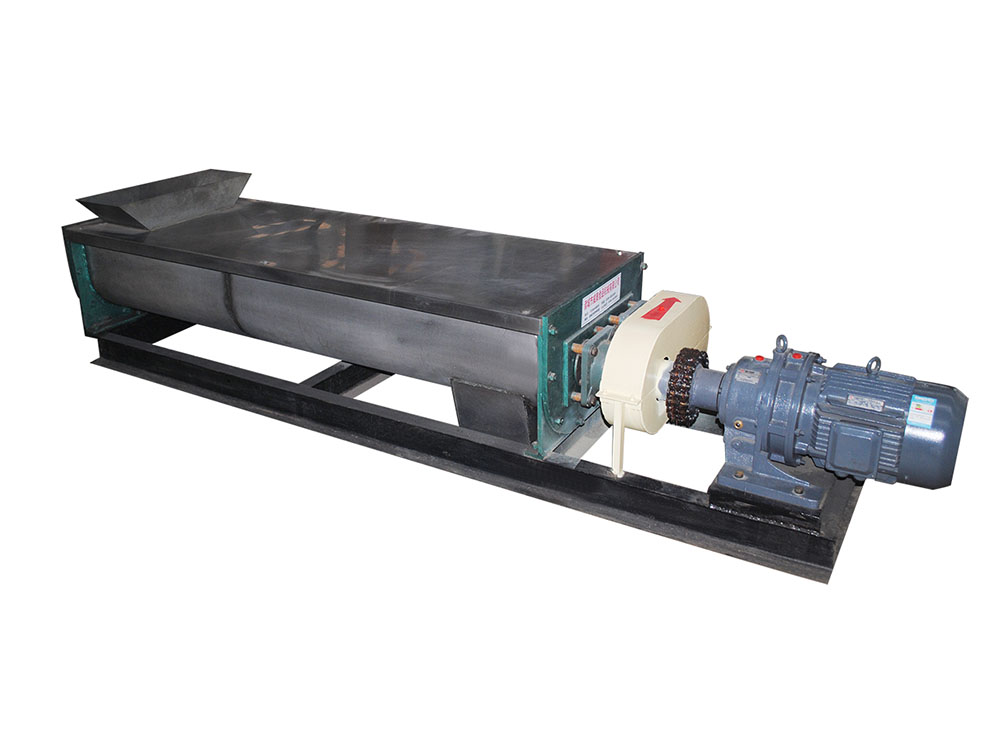

Ob chav ncej sib xyaw tshuab

Lub kauj vauv ob leeg ua ke kuj tseem hu ua cov dej ntub dej thiab qhuav tov khoom. Cov ntaub ntawv hauv tshuab tau raug rau cov khoom sib txuas los ntawm ob lub rotors hauv cov lus qhia. Cov paddles nrog cov tsiaj cov tsiaj tig tig rau sab nraud raws sab hauv phab ntsa sab hauv ntawm lub tshuab siv, thiab cov khoom siv tsiaj tig mus rau sab laug thiab sab xis. Qhov chaw tsis muaj cheeb tsam yog tsim nyob rau ntawm qhov kev sib tshuam ntawm ob lub ntsuas cua. Ntawm thaj chaw no, tsis hais txog cov duab, qhov loj thiab tuab ntawm cov khoom, cov khoom yuav tuaj yeem ntab rau hauv lub xeev lub nrawm nrawm, yog li cov khoom siv tuaj yeem tsim txuas ntxiv thiab hloov mus rau hauv lub tshuab ua haujlwm, cuam tshuam txiav kom ua tiav qhov nrawm thiab kev maj mam ua zoo. Lub tshuab txais yuav ntau qhov zawj labyrinth thiab ntim cov thooj sib txuam, uas muaj kev ntseeg siab khi thiab hnav lub teeb ua haujlwm. Uniform humidification, kev ua haujlwm txhim khu kev qha thiab kev tswj qis.

Khoom nta

Muaj lub cev muaj zog tshaj plaws, cov khoom siv tuaj yeem sib xyaw tusyees hauv lub sijhawm luv. Nws yog qhov tshwj xeeb hauv kev sib xyaw cov khoom siv nrog qhov sib txawv loj hauv kev sib tsoo, mesh loj, fluidity.

Kev ua tau zoo thiab siv

Cov ntxaib-sib xyaw ua ke yog qhov tsim nyog rau kev sib xyaw cov tuab thiab tuab ntawm cov ntaub ntawv qhuav thiab ntub dej hauv cov hmoov txhuv nplej siab, cawv, thiab pub kev lag luam, kom cov khoom ntub ntawm qhov nkag mus hauv lub tshuab ziab khaub ncaws tsis yooj yim rau lo rau ntawm phab ntsa. Cov. Lub tshuab no muaj qhov zoo ntawm cov qauv kev sib txawv, kev hloov ua kom zoo, tsis pub ya cov plua plav, thiab lwm yam, ua tau raws li kev tiv thaiv ib puag ncig, thiab kev tsim ua yog 5-100 tons / teev. Nws yog cov khoom siv zoo tshaj plaws rau ziab thiab pulping hauv kev lag luam cov hmoov txhuv nplej siab. Cov khoom siv nkag mus rau hauv lub thawv dhau ntawm lub taub pub rau tus pub khoom noj, thiab ob lub tshuab rab ntaj, uas tau muab cov kauv faib rau sab laug thiab sab xis, yog qhov sib hloov ua ke, thiab cov khoom siv humid txuas ntxiv raug thawb tawm ntawm qhov chaw pub khoom noj.

1. Cov khoom siv hloov tau yooj yim

Cov khoom siv tuaj yeem ua cov pa roj carbon steel, manganese steel, ss304, 316L thiab 321; dhau li ntawm, cov khoom sib txawv kuj tuaj yeem raug siv los ua ke ntawm kev sib tiv tauj ib sab nrog cov khoom siv raw thiab cov ntu tsis sib cuag nrog cov khoom siv raw.

Cov kev kho deg rau stainless hlau muaj xws li sandblasting, wiredrawing, polishing, daim iav polishing, txhua tus tuaj yeem siv rau ntau qhov chaw ntawm kev sib tov.

2. Kev ntseeg siab tsav

Lub zog tsav, lub zog thiab nrawm yog txawv raws li cov khoom siv sib txawv, pib txoj kev, thiab txheej txheem.Because ntawm lub meshing kev sib raug zoo rau cov paddles, ob chav ncej tsav yuav tsum tau nruab nrog lub peev xwm synchronous.

3. Kev ua hauj lwm siab ntau hauv chav ua haujlwm

Raws li cov yam ntxwv ntawm cov khoom siv raw, tus paddle tuaj yeem hloov kho thiab tsim qauv kom haum, piv txwv li ntxiv hnav-pov thawj phaj, Teflon phaj, thiab pom-toothed paddle.

Ob chav ncej duav tov khoom tuaj yeem txuas ntxiv kev kub ceev rhuav bar sab hauv lub thawv, cov khoom tawg yooj yim tom qab nws ntws.

4. Kev rho tawm zoo Lub tshuab

txheem txheem valve rau ob chav ncej paddly tov khoom yog ntxaib pneumatic planar nrov plig plawg li qub. Thaum kaw lub valve, lub dav hlau flaps phim cov khoom sib xyaw ua ke txig, qhov no ua rau tsis muaj qhov sib xyaw ua kom tuag thiab zoo dua cov nyhuv sib xyaw.

Cov yam ntxwv thiab khoom siv tsis dhau

|

Qauv \ parameter |

HL2600 |

HL3200 |

HL4500 |

HL6000 |

|

|

Siab tshaj plaws import thiab export conveying nrug distance mm)

|

2600 |

3200 |

4500 |

6000 |

|

|

Peev xwm ntau lawm (T) |

1-10 |

5-15 |

10-20 |

15-25 |

|

|

Ntxaiv ceev |

49 |

49 |

46 |

49 |

|

|

Qauv qis |

Jzq200 |

Jzq200 |

Jzq350 |

Jzq400 |

|

|

Lub cev muaj zog |

qauv |

Y112M |

Y132S |

Y132M |

Y160M |

|

lub hwj chim |

4 |

5.5 |

7,5 |

11 |

|